Kwamfutocin Semiconductor sune ginshiƙin fasahar sadarwa da kuma wata muhimmiyar fasaha da masana'antu da ƙasashe ke fafatawa don haɓaka.Wafer ɗin Wafer, a matsayin muhimmin abu don kera kwakwalwan semiconductor, yana taka muhimmiyar rawa a ci gaban masana'antar semiconductor ta China. Dangane da karfin kera wafer, China ta riga ta jagoranci a duniya, amma yayin da "karancin guntu" na duniya ke kara karfi, zai kara hanzarta fadada karfin aiki.

1. Bayanin Aikin

Wani reshe na masana'antar semiconductor ta cikin gida da aka jera, a matsayinsa na babban ɗan wasa a masana'antar kayan bayanai na lantarki ta ƙasa, ya himmatu ga bincike da haɓakawa, ƙera kayan semiconductor, kayan lantarki na musamman, na'urorin semiconductor da sauran fasahohi. Babban samfurin shine wafer silicon mai narkewa na lu'ulu'u guda ɗaya na yankin semiconductor, tare da manyan ƙarfi uku na duniya da kuma kaso na kasuwar cikin gidasama da kashi 80%.

Domin hanzarta faɗaɗa ƙarfin aiki, kamfanin ya zuba jari kimanin dala biliyan 3 don fara gina babban aikin samar da wafer silicon wafer da kera don haɗa da'irori a cikin birnin Yixing, lardin Jiangsu. An ƙaddamar da mataki na biyu na aikin a shekarar 2021, tare da bin ƙa'idar ci gaba ta "Masana'antu 4.0" da kuma shirin amfani da masana'antu masu wayo a duk faɗin layin don cimma aikin atomatik, bayanai, da gina bitar mai wayo. Bayan kammalawa, jimlar ƙarfin samarwa zai zama wafer epitaxial inci 8 220000, wafers mai goge inci 12 200000, da wafers epitaxial inci 150000 a kowane wata, wanda hakan zai zama tushen samar da wafer silicon tare da fa'idodi na duniya. Saboda haka, dangane da ajiyar kayan aiki na ƙungiyar,ROBOTECH ta inganta matakin hankali, bayanai, da kuma sarrafa kansa na tushen samar da kayayyaki ta hanyar aiwatar da tsarin adana kayayyaki masu wayo na zamani..

2. Aikinplanning

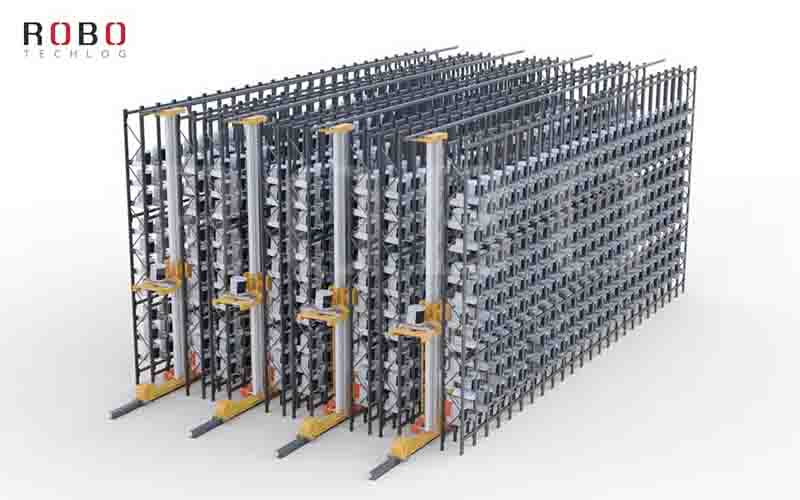

ROBOTECH ta yi amfani da sararin tsaye na mita 6 gaba ɗaya na tushen samar da kayanta kuma ta tsaraMa'ajiyar ajiya ta atomatik ta nau'in akwati mai layi 4don samun damar samfuran wafer na semiconductor, wanda zai iya ɗaukar jimlar sama daWuraren ajiya 2000, yadda ya kamata ƙara ƙarfin ajiya na wafersSaboda wafer ɗin yana cikin siffar zare, mai ɗaukarsa yana ɗaukar wani akwati na filastik mai haske na musamman mai girman 330 * 330 * 300 don sauƙin shiga wafer ɗin, tare da matsakaicin nauyin kilogiram 50.An magance matsalar tsarin adana wafer mai sarkakiya da kuma ƙarancin amfani da sarari a cikin rumbunan ajiya na gargajiya, inda aka cimma ci gaba biyu a fannin amfani da sararin samaniya da inganci.

• Tsarin crane mai tara kaya na jerin zebra

• Tsarin samarwa na mita 100/min & awanni 24 & 63P/h a kowace zagaye

Dangane da ingantaccen aiki, ROBOTECH yana zaɓarna'urar tara jerin zebracranetsarindon kwararar kayan aiki mai ƙarfi, tare da saurin kwance na100m/min, wanda ya dace daTsarin samarwa na awanni 24na tushen samarwa, kuma ingancin ajiya zai iya isa ga63P/h a kowace zagaye.

3. Ba tare da tsoro na ƙalubale ba, kirkire-kirkire na musamman

•Etabbatar da juriya ga ƙura da girgiza

•Keɓancewa mara daidaituwa

•Una'urar firikwensin ltrasonic

•TAna sanya mai ɗaukar kaya a kusurwar digiri 5 a kan shiryayye da cokali mai yatsu

Kalubale na 1

Sifofin ajiya na wafers na semiconductor sune:tabbatar da juriyar ƙura da girgiza, in ba haka ba yana da sauƙi a lalata wafers masu rauni. Dangane da wannan, ROBOTECH ta haɓaka tsarin injina na crane na stacker zuwagyare-gyare marasa daidaitoMisali, ana amfani da layukan ƙasa na aluminum alloy maimakon layukan gargajiya, ana amfani da ginshiƙan aluminum masu ƙarfi da sanyi maimakon ginshiƙan ƙarfe, ana amfani da ƙafafun roba da aka rufe maimakon ƙafafun ƙarfe, ana amfani da ɗaga bel na lokaci maimakon ɗaga igiyar ƙarfe, kuma ana ƙara murfin da ba ya ƙura a kan dandamalin kaya.Tun daga farkon matakin ƙirar kayan aiki, an rage tasirin ƙura da girgiza akan kayayyaki, an rage haɗarin gurɓatawa a cikin bitar da ba ta ƙura ba,kuma an inganta yawan amfanin gona. Matsayin tsafta zai iya biyan buƙatun muhalli na Aji 1000.

Kalubale na 2

Saboda akwatin filastik mai haske na mai ɗaukar wafer, ba za a iya amfani da na'urori masu auna hoto na gargajiya don gano kaya ba. ROBOTECH ta ƙirƙiro wani sabon salona'urar firikwensin ultrasonicdon gano kaya, wanda zai iya gano yanayin kaya ta atomatik akan shiryayye da fale-falen kaya. Kuma an sanye shi da kyamara da allon aiki na hannu don cimma daidaiton gani da bin diddigin duk kayan a duk tsawon aikin, yayin da kuma magance matsaloli da warware kurakurai ta hanya mafi dacewa.

Kalubale3

Don hana wafer ɗin zamewa daga mai ɗaukar kaya,Ana sanya mai ɗaukar kaya a kusurwar digiri 5 a kan shiryayye da cokali mai yatsuAna samun daidaiton matsayi mai kyau da kuma forking mai karko ta hanyar saka ramin ƙasa na akwatin wafer a cikin fil ɗin matsayi guda uku na kayan aiki na musamman don tara dandamalin kaya na iska don ajiya. Bayan gwaji akai-akai, daidaiton matsayi na ƙarshe ya kai ga cimma daidaiton matsayi± 2mm, kuma santsi mai yawo ya kai99.99%Bugu da ƙari, kayan aikin suna amfani da na'urori daban-daban masu haɗa kai, wanda hakan ke inganta gabaɗaya yadda ya kamatakwanciyar hankali da aminci.

A matsayinsa na ƙwararre a fannin hanyoyin adana kayayyaki ta atomatik, ROBOTECH ta gina hanyoyin samar da kayayyaki masu wayodon kayan wafer waɗanda ba su da gurɓatawa kuma ana iya gano su a ainihin lokaci, bisa ga kayan aiki na zamani da tsarin da ya dace.

Nasarar aiwatar da wannan aikin yana nuna alamaringantaccen ci gaba a cikin ajiyar wafer ta atomatik na semiconductor wafer, kuma yana nufin cewaROBOTECH za ta shiga fagen semiconductor a hukumance, ƙarfafa kamfanonin semiconductor tare da hanyoyin sarrafa bayanai masu amfani da dabaru. A nan gaba, ROBOTECH za ta ci gaba da bincike, tara ilimin masana'antu, inganta amfani da albarkatu, da kuma cimma ci gaban inganci gaba ɗaya.

Kamfanin NanJing Inform Storage Equipment (Group) Ltd.

Wayar hannu: +86 25 52726370

Adireshi: No. 470, Yinhua Street, Lardin Jiangning, Nanjing Ctiy, China 211102

Yanar Gizo:www.informrack.com

Imel:[an kare imel]

Lokacin Saƙo: Afrilu-11-2023